Plug & Play Production Engineering Advisors

We are the industry’s first plug & play production engineering advisory service for the next generation of oil & gas operators.

We are the industry’s first plug & play production engineering advisory service for the next generation of oil & gas operators.

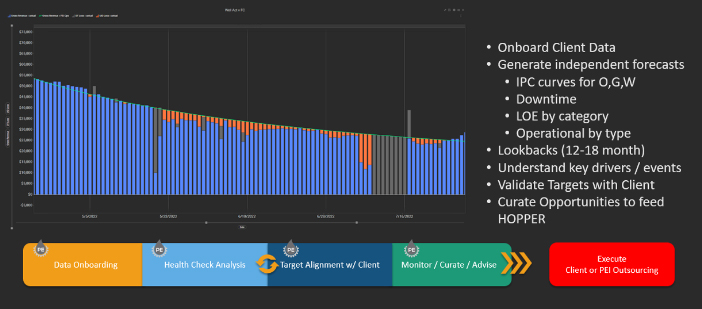

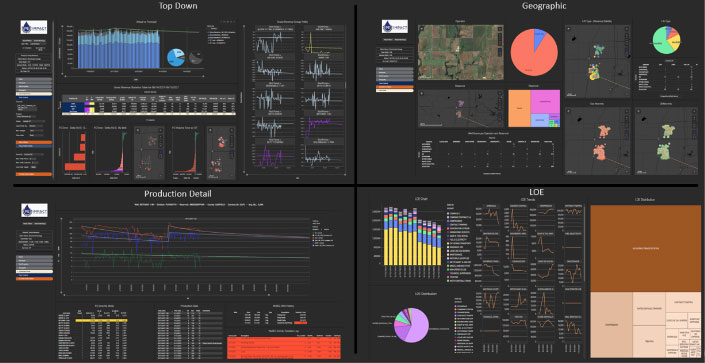

Our innovative engineers use best-in-class technology alongside proven processes & workflows to provide the answers and peace of mind every management team needs in order to focus on strategic initiatives and achieve enhanced return on investment.

The cyclical nature of our industry often creates a lack of focus on base management as shifting priorities compete for scarce engineering resources.

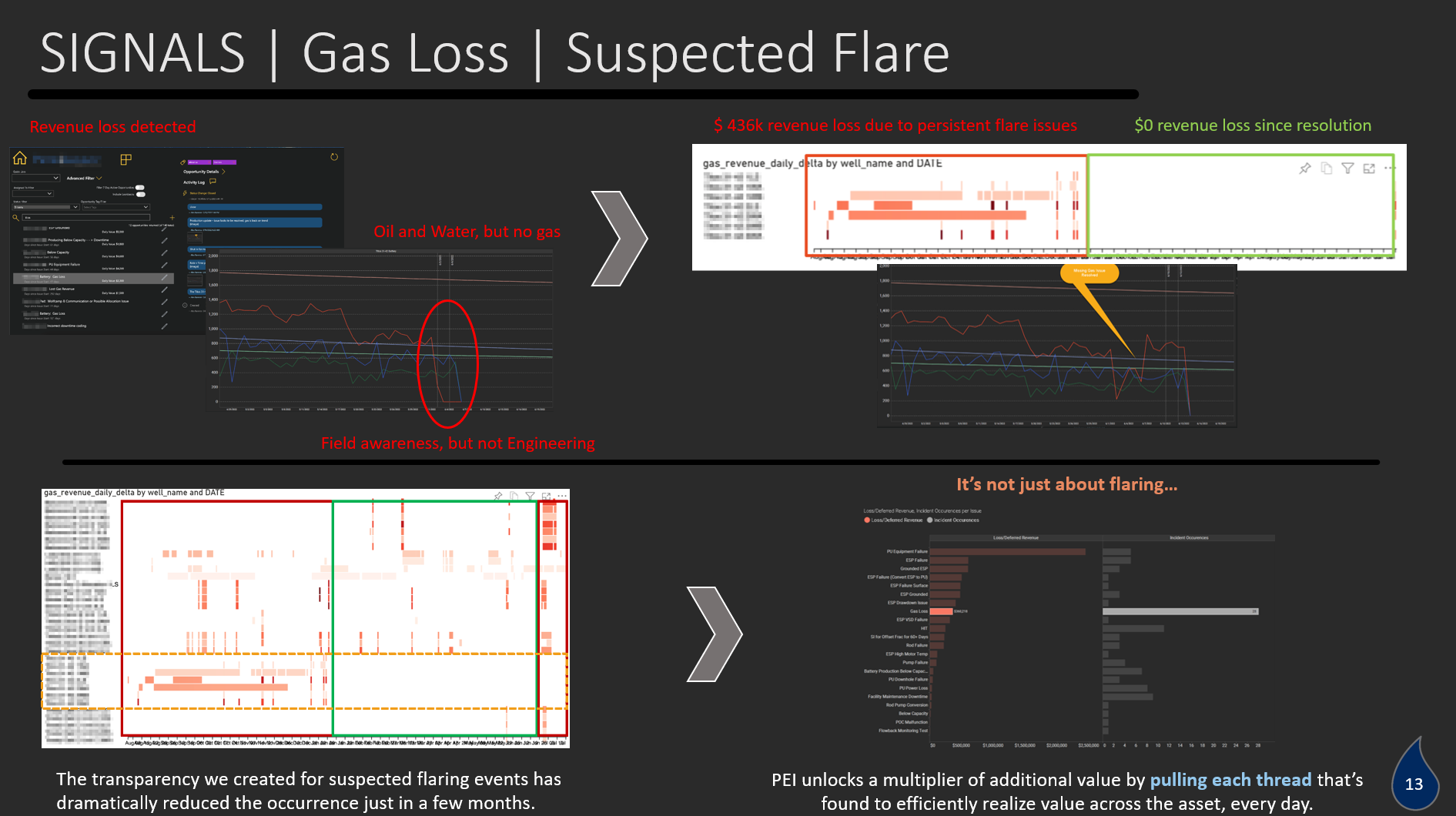

Operators rarely take advantage of the value field staff can generate when they are properly integrated into the production team.

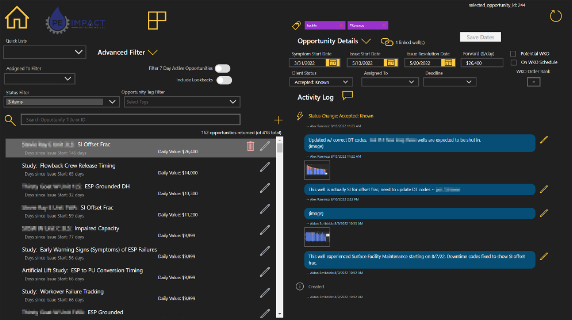

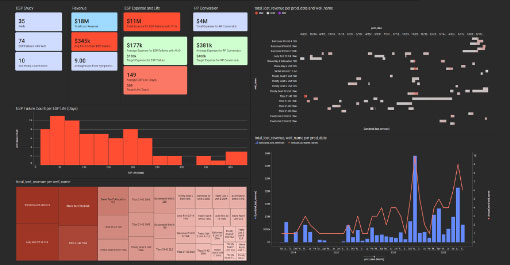

Many operators are still using spreadsheets & email to track, communicate, and make critical production management decisions. This inefficiency causes millions of dollars of waste each year.

Efficient & effective base production with relentless cost control creates a sustainable competitive advantage in any market environment.

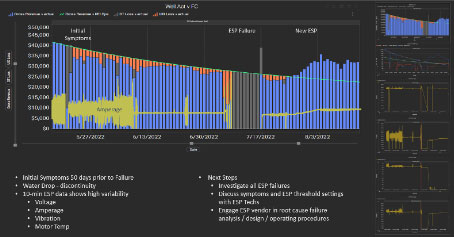

Building engagement with field staff relies on getting the right information to the right people fast enough to matter to drive cost & production.

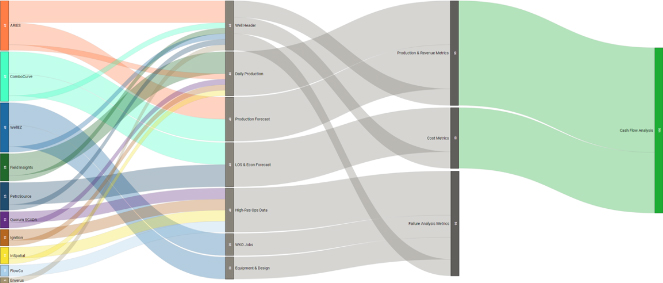

Process automation & technology can enable better data transparency & quality engineered analysis with a fraction of the manpower.

The cyclical nature of our industry often creates a lack of focus on base management as shifting priorities compete for scarce engineering resources.

Efficient & effective base production with relentless cost control creates a sustainable competitive advantage in any market environment.

Operators rarely take advantage of the value field staff can generate when they are properly integrated into the production team.

Building engagement with field staff relies on getting the right information to the right people fast enough to matter to drive cost & production.

Many operators are still using spreadsheets & email to track, communicate, and make critical production management decisions. This inefficiency causes millions of dollars of waste each year.

Process automation & technology can enable better data transparency & quality engineered analysis with a fraction of the manpower.

Focused on bottom line, costs, and margins

Optimize from sand face to cash register

Pumper to C-suite management

Private, Small Cap, and Large Cap experience

Shale, Tight Sand, Conventional, Deep HP-HT

Fit-for-purpose application of technology

Recognized as low cost operator

Environmentally and Safety conscious

Proven track record of success

Progressive thinkers for 2020 and beyond